Historic Overview of U.S. Fixed Offshore Platforms – Part II

June 2025

By Bryan Wood PE and Allan Hayes PE

This is the second of a three-part overview of the history of U.S. fixed offshore platforms. While this is a highly specialized aspect of engineering involving a comparatively small number of civil engineering professionals, it is an expertise that not only supports an industry that’s critical to the production of a most valuable national resource but also delivers on our ever-increasing demand for energy.

Pioneers, by definition, are those who first use or apply a new method or area of knowledge. The fixed offshore platform we know today as a “first” required civil engineers to solve and define many smaller problems. Engineers worked together with contractors, research institutes, and academia (University of Texas at Austin, Texas A&M University), while also initially using trial and error to develop solutions for these platforms.

The first big challenge was understanding the loading from storm waves and determining the correct wave height for design. Wave height was crucial because if waves hit the platform’s top it could cause it to topple. Early engineers had little data on storm waves so they relied on meteorological research, which suggested using the highest wave recorded in the last 25-yrs. for design. However, the industry learned from failures after several powerful hurricanes hit the Gulf of Mexico in the 1960s, toppling many platforms.

In 1969 the American Petroleum Institute (API) published the first edition of its guidelines (API RP 2A) for designing fixed offshore platforms. The industry eventually agreed on using the wave height from a 100-yr. return period hurricane and recommended an “air gap” above the wave crest for safety.

Another challenge was using open ended tubular piles for offshore structures. These piles, which develop nearly all of their capacity from skin friction as opposed to end bearing, were rarely used on land before so little knowledge was available for their design. Tubular steel was also rare after World War II so one company ingeniously used what was available at the time for one platform; gun barrels intended for a battleship. These piles needed to support heavy loads and resist forces from waves, wind, and currents. Engineers also had to understand the soil conditions offshore, particularly in the Gulf of Mexico, where they had little data about the mucky clay soils.

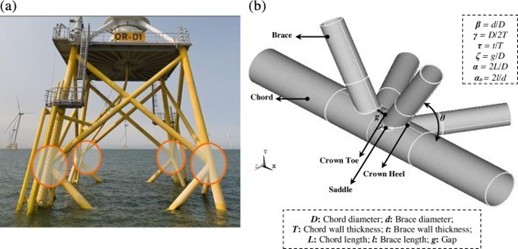

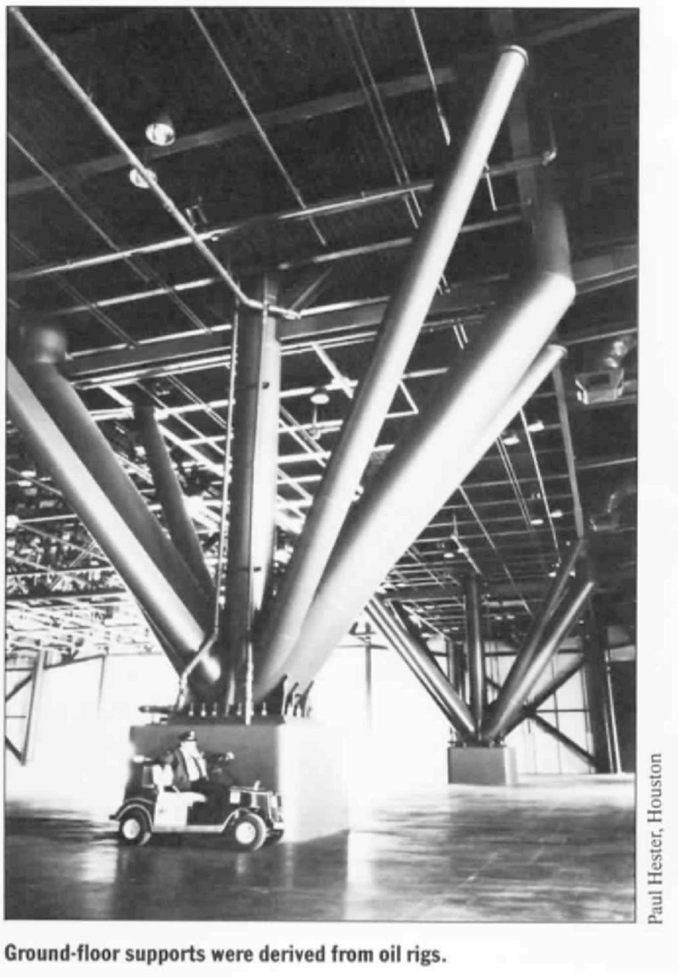

As platforms became more common, engineers faced challenges in constructing the tubular structures known as “jackets”. These structures were made by welding multiple pipes, and the connections at these intersections were called T, K, and Y joints. Welders had to undergo special training for these complex welds. Tubular structures quickly became the standard because they minimized the forces from moving water.

Engineers also realized in the early years that it was more efficient to weld as much of the jacket frames on the ground as possible and then roll them into position by lifting using cranes. As platforms moved into deeper waters new issues arose, including fatigue in the structures. Engineers found that widening the base of the jacket helped reduce the natural vibrations of the platform, and the use of tougher materials to construct the joints allowed for deeper platforms, reaching 1,000-ft. or more.

Notable contributions were made by engineers like Peter W. Marshall from Shell Oil and organizations like Southwest Research Institute, which played key roles in improving the technology and research necessary for offshore platforms to evolve.